Acrylic has quietly become one of the most versatile and inspiring materials in modern design. From sleek retail displays to architectural installations and lighting solutions, acrylic continues to redefine how designers and manufacturers approach both functionality and aesthetics. But behind every clear, glossy panel or intricately cut shape lies a story of innovation — a story about how new ideas, technologies, and craftsmanship are driving the acrylic manufacturing industry forward.

The Rise of Acrylic in Modern Design

Acrylic, also known as PMMA (Polymethyl Methacrylate), first gained popularity as a glass substitute decades ago. It offered excellent transparency, impact resistance, and weather durability — properties that made it an ideal choice for industries such as construction, retail, and advertising. However, what truly pushed acrylic into the spotlight was its creative potential.

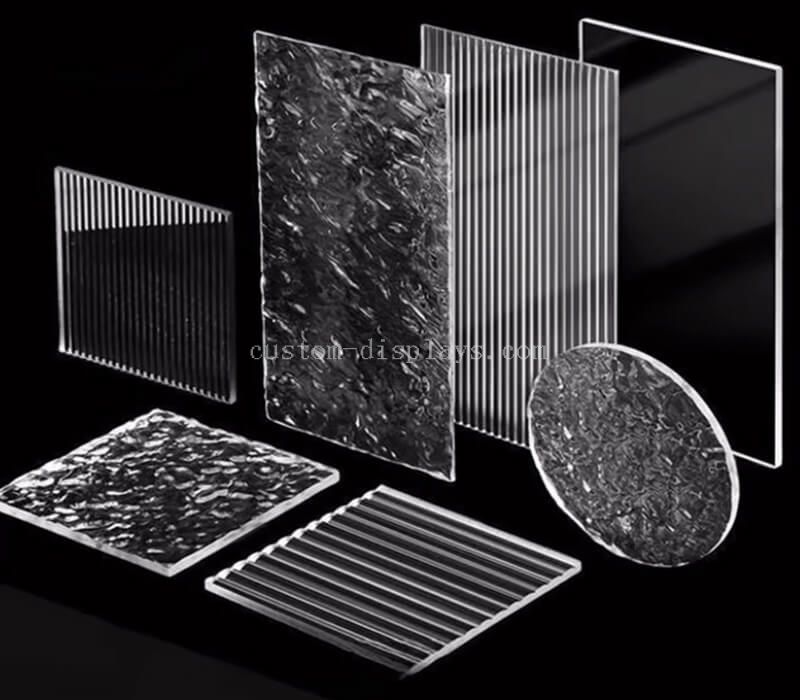

Today, acrylic is no longer seen as a simple alternative to glass. Designers now embrace it as a key element in creating modern, clean, and customized visuals. Its flexibility in shaping, coloring, and surface finishing allows brands to express their identity in ways that traditional materials simply can’t. Whether it’s a high-end cosmetic display stand, a luxury furniture piece, or an illuminated signage board, acrylic provides the perfect balance between beauty and practicality.

Innovation Driving the Future

The new wave of acrylic manufacturing is not only about precision cutting or polishing — it’s about combining creativity with technology. Modern manufacturers are investing in laser cutting, CNC engraving, and UV printing techniques that make customization more detailed and efficient than ever.

For example, laser engraving allows intricate logos, patterns, and text to be added directly onto the surface without distortion or residue. Meanwhile, UV printing opens the door for full-color, high-resolution graphics that turn plain panels into works of art. These innovations are especially valuable in retail environments, where visual impact and branding play a critical role in customer experience.

Another growing trend is eco-friendly acrylic production. Many leading factories are shifting to recyclable materials and sustainable processes to reduce waste and carbon emissions. By improving recycling systems and developing new formulations that require less energy during production, the acrylic industry is taking meaningful steps toward a greener future.

Design Meets Functionality

One of the main reasons acrylic continues to dominate in display and retail industries is its unique ability to merge form and function. For example, in custom retail displays, acrylic can be molded into L-shaped stands, layered platforms, or multi-tiered shelves that not only hold products but also enhance their presentation. The material’s clarity ensures products remain the visual focus, while its strength guarantees long-lasting use.

Moreover, acrylic’s adaptability goes beyond retail. Interior designers and architects are now integrating acrylic panels into furniture, partitions, and lighting elements. The material’s smooth finish and ability to transmit or diffuse light make it ideal for creating modern, minimalistic environments.

Precision Manufacturing: The Heart of Quality

Behind every elegant acrylic product is a combination of skilled craftsmanship and precise engineering. Cutting, bending, polishing, and assembling acrylic requires not just advanced machines but also experienced technicians who understand how the material behaves under heat and pressure. A small mistake can lead to cracks or uneven edges, so maintaining strict quality control is essential.

At the same time, computer-aided design (CAD) and automation have significantly improved production accuracy and repeatability. Manufacturers can now transform a designer’s digital concept into a finished product within days — something that was nearly impossible a decade ago. This efficiency helps businesses save time, reduce costs, and bring innovative products to market faster.

Customization: The Key to Brand Differentiation

In the world of modern retail, customization is no longer optional — it’s expected. Every brand wants its display solutions to reflect its identity and values. Acrylic offers unmatched flexibility in this area. It can be shaped, tinted, or layered to match any color scheme or aesthetic. Combined with techniques like laser cutting and UV printing, brands can easily achieve a distinctive, premium look that enhances customer engagement.

Whether it’s a custom countertop display for luxury cosmetics or a freestanding product tower for electronics, acrylic provides endless design possibilities. This flexibility is one of the main reasons why global retailers and marketing agencies continue to rely on professional acrylic manufacturers for their display solutions.

Looking Ahead

As technology continues to evolve, so will the acrylic manufacturing industry. We can expect to see smarter, more sustainable materials, advanced digital fabrication tools, and even stronger collaborations between designers and manufacturers. The future of acrylic is not just about clarity or durability — it’s about creativity without limits.

In the end, what truly drives progress in this field is the passion for innovation. From the smallest display stand to large architectural installations, every acrylic creation represents a perfect harmony between material science, technology, and human imagination.

At Custom Displays, we believe that innovation in acrylic design will continue to inspire industries worldwide — proving that even a transparent material can have a bold and transformative impact on how we see and shape our world.