In the world of materials science and manufacturing, few substances have shown as much versatility and staying power as acrylic. Often known by its trade name Plexiglas or Lucite, acrylic has been a staple in various industries for decades. But lately, it’s undergoing a fascinating shift—from its roots in straightforward, everyday applications to cutting-edge innovations that push the boundaries of what’s possible. This transformation isn’t just about new tech; it’s a story of adaptation, creativity, and responding to modern demands like sustainability and customization. Let’s dive into how acrylic products are evolving, and why this matters for businesses, designers, and consumers alike.

First off, a quick rewind to the basics. Acrylic, or polymethyl methacrylate (PMMA) if we’re getting technical, was invented in the early 20th century. It hit the big time during World War II, when it was used for aircraft canopies because of its clarity, lightness, and shatter-resistant properties—way better than glass in those high-stakes situations. Post-war, it trickled down into civilian life. Think about those classic neon signs glowing on city streets, or the protective barriers in banks and stores. Acrylic’s transparency, durability, and ease of molding made it ideal for displays, signage, and even furniture like coffee tables or chairs with that sleek, modern vibe.

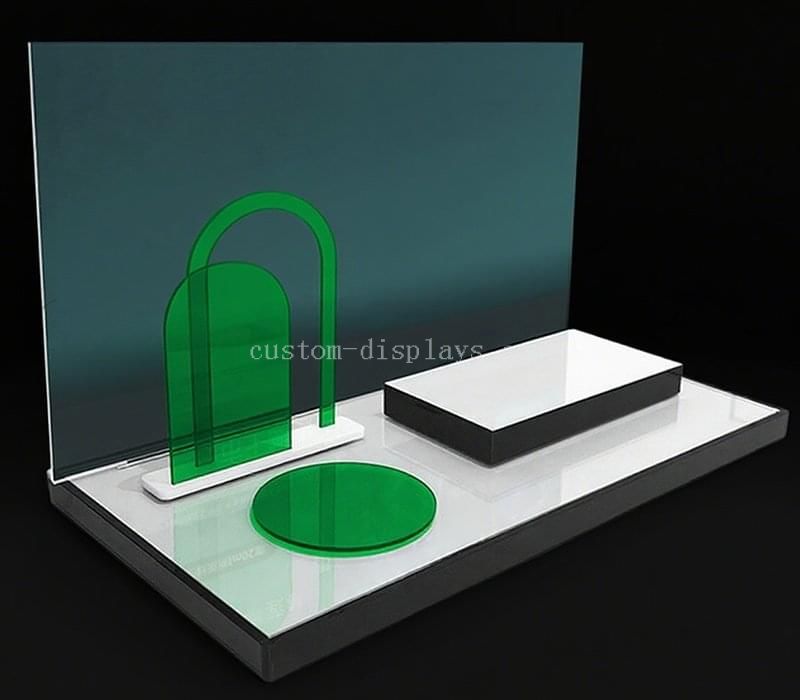

In traditional settings, acrylic products have always been about reliability and aesthetics. For instance, in retail, acrylic shelves and cases highlight products without stealing the show. They’re lightweight, which means easier installation and lower shipping costs compared to heavier materials. And let’s not forget the DIY crowd—home crafters love acrylic for custom keychains, picture frames, or even aquarium builds. It’s forgiving to work with; you can cut, bend, and polish it without needing fancy equipment. But here’s the thing: while these uses are timeless, the market has been demanding more. With global competition heating up and consumers wanting eco-friendly options, sticking to the old ways just isn’t cutting it anymore.

That’s where the innovation kicks in. The transformation of acrylic products is driven by a mix of technological advances and shifting priorities. One big leap is in material engineering. Traditional acrylic can yellow over time or crack under extreme conditions, but new formulations are tackling that head-on. UV-resistant variants now last longer outdoors, making them perfect for architectural elements like skylights or outdoor signage that withstands harsh weather. And then there’s the push toward sustainability. Acrylic isn’t biodegradable, which has been a knock against it, but manufacturers are stepping up with recycled acrylic options. Companies are now producing sheets from post-consumer waste, reducing the environmental footprint without sacrificing quality. It’s a win-win—businesses get to tout their green credentials, and the planet gets a breather.

But the real excitement comes from how acrylic is integrating with emerging technologies. Take 3D printing, for example. Acrylic-based resins are now used in additive manufacturing, allowing for intricate designs that were impossible with traditional casting or injection molding. Imagine prototyping a complex medical device or a custom jewelry piece in hours, not weeks. This speed and precision are revolutionizing industries like healthcare and fashion. In medicine, acrylic is being used for prosthetics and dental implants, but innovative twists include bio-compatible versions that mimic human tissue more closely. Or consider the automotive sector: lightweight acrylic composites are replacing metal parts, improving fuel efficiency in electric vehicles.

Another frontier is smart materials. Acrylic isn’t just passive anymore; it’s getting embedded with tech. Think LED-integrated acrylic panels for interactive displays in museums or retail spaces. These can change colors, display information, or even respond to touch. I’ve seen installations where acrylic walls light up based on visitor movement—it’s like bringing a static material to life. And in the realm of optics, acrylic lenses are evolving with anti-fog and anti-scratch coatings, finding new homes in VR headsets and augmented reality glasses. The pandemic accelerated some of this; acrylic barriers became ubiquitous, but now they’re being upgraded with antimicrobial additives to fight germs proactively.

Of course, no transformation is without challenges. Scaling up these innovations can be costly, and not every manufacturer has the R&D budget to experiment. There’s also the skills gap—workers trained in traditional fabrication might need upskilling for digital tools like CNC machines or laser cutters that work seamlessly with acrylic. But the payoffs are huge. Take a company like Acme Acrylics (a fictional stand-in for real players in the field); they’ve pivoted from basic sheet production to custom, laser-etched products for e-commerce brands. Their sales jumped 40% by offering personalized items, like engraved phone cases or branded awards. It’s proof that innovation isn’t just buzz—it’s bottom-line business.

Looking ahead, the road for acrylic products seems paved with even more possibilities. With the rise of the circular economy, expect more closed-loop recycling systems where old acrylic gets reborn into new products. Nanotechnology could enhance properties further, making acrylic self-healing or super-hydrophobic (water-repelling). And as AI enters design processes, we might see algorithms optimizing acrylic structures for strength and minimal material use, cutting waste even more.

In wrapping this up, the journey from traditional to innovative acrylic products reflects broader trends in manufacturing: adaptability is key. What started as a simple substitute for glass has blossomed into a material that’s smart, sustainable, and endlessly customizable. For anyone in design, retail, or tech, keeping an eye on acrylic’s evolution could spark the next big idea. After all, in a world that’s constantly changing, materials like acrylic remind us that even the classics can reinvent themselves.